Petrochemical & Industrial Plants

Annual “Turn Around” or even unexpected shutdown is a good time to clean machinery, turbines, pumps, pipes, valves, boilers and other equipment that accumulate dirt and contaminant due to process, weather and aging. However, why wait? With dry ice blasting some jobs can be done in situ often no loss of production is required. Using dry ice blasting saves down time and cleaning time compared to other type of cleaning.

Automotive, Railway & Aeronautics

Automobile Industry benefit from a considerable reduction of cleaning time of Welding robots in body shop, moulds for thermoplastic / PUR / rubber / aluminium, motors, reconditioning car parts and more.

BEFORE

Cleaning motors with the dry ice blasting system from CRYONOMIC® works fast and is environmentally friendly!

AFTER

All contamination from this motor has been removed with dry ice blasting

Electricity / Power Generation

Dry ice cleaning is highly recommended for cleaning dead or live equipment and can be used for cleaning : stator-rotor installations / turbines / transformers and substations / motors AC/DC / switchboards and electric cabinets / nuclear decontamination and more.

BEFORE

CRYONOMIC® has special guns for cleaning electrical cabinets under tension

AFTER

A nice result after cleaning with dry ice

BEFORE

Cleaning electrical cabinets with dry ice blasting can be done easily and without extra waste

AFTER

The result of cleaning with CRYONOMIC® dry ice machines

Printing Industry

The printing industry broadly recognises dry ice cleaning as the most efficient and fastest method for cleaning printing presses and equipment including: drums, grippers and rollers / side walls and ink trays / gears, print decks and guides / delivery units and feeders / conveyors, gluers / paper converting equipment and more.

BEFORE

Glue and paper residues easily removed with dry ice

AFTER

Clean printing press using CRYONOMIC® dry ice machines

Education, Schools, Government buildings, Museums

Building walls, parks and monuments are often victims of vandals. Easily remove graffiti using our dry ice cleaning. Precious artifacts are easily restored and maintained using the right dry ice blaster as compared to other techniques there is no abrasion.

Chemical Industry

Easily remove residues and hazardous by products using dry ice blasting which leaves no chemical contamination or wetting of the surface.

Food & Agriculture

The food industry is rapidly discovering dry ice cleaning for: Continuous conveyor ovens, fryers / Industrial waffle moulds/ Baked -on residues, carbon build-up, grease / Knife blades, mixing equipment/ Conveyors, …all with no residual cleaning chemicals after the job is complete

BEFORE

A dirty metal conveyer

AFTER

Dry ice blasting leads to effective removal of fat and burned residues

BEFORE

A dirty metal wheel

AFTER

Built up fat and residues removed by dry ice blasting

Rubber & Moulding industry

Thanks to dry ice blasting the rubber industry benefits from considerable reduction of:

– cleaning time of: moulds, presses, mixers and machinery

– an increase of the lifetime of the moulds

BEFORE

AFTER

Construction & Building Renovation

Dry ice cleaning is rapidly becoming the preferred process for property restoration and is successfully being applied for: fire restoration, façade cleaning, historic and listed building restoration, monument restoration, water damage restoration and mould removal, decontamination, chewing gum removal, cleaning construction equipment, paint stripping, etc.

BEFORE

Grafitti removal on large surfaces done with wide nozzles

AFTER

Large wall after graffiti removal

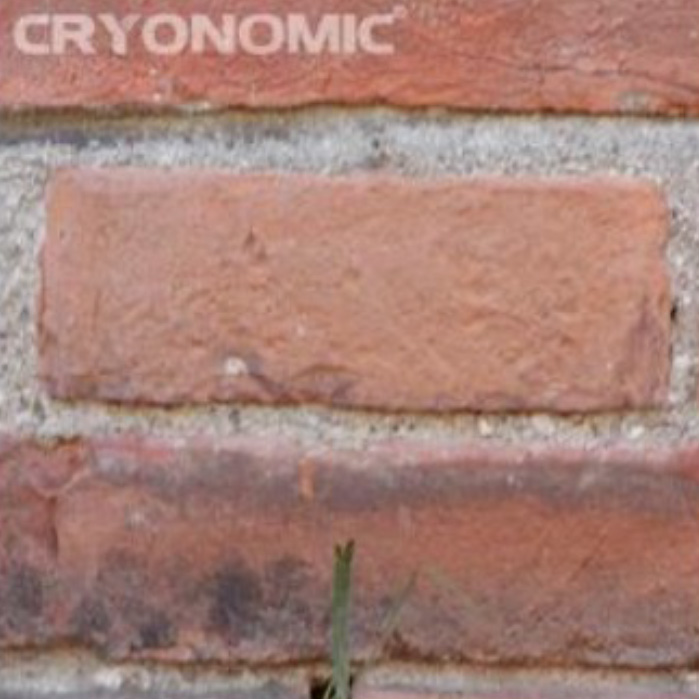

BEFORE

Dry ice cleaning makes it possible to remove paint without damaging bricks

AFTER

Paint removed from bricks using dry ice blasting

Metal processing

Thanks to dry ice blasting the Foundry industry benefits from savings related to a considerable reduction of cleaning time of: moulds / kernel boxes / production lines, … It reduces radically the time of removing residues and release agents.

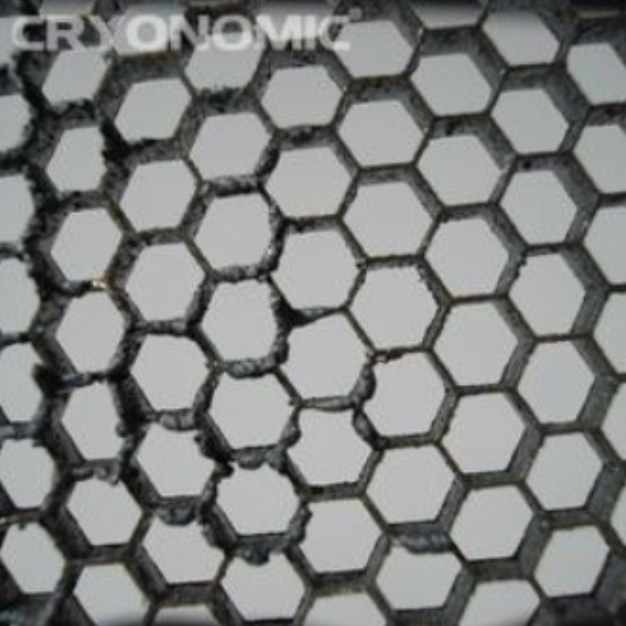

BEFORE

Deburring laser cut parts

AFTER

Image show the left part not cleaned, with the right part CRYONOMIC® deburred